1. Introduction: New EU PFAS Regulations and Testing Standards (2024–2025)

The European Union has taken decisive action against per- and polyfluoroalkyl substances (PFAS) with the publication of REGULATION (EU) 2024/2462 on September 20, 2024. This landmark regulation targets perfluorohexanoic acid (PFHxA), its salts, and related substances, marking a significant escalation in the EU's war against "forever chemicals."

Simultaneously, the European Committee for Standardization released EN 17681-1:2025 in April 2025, introducing a revolutionary testing methodology that uses alkaline hydrolysis to detect PFAS previously hidden in polymeric structures. This stricter testing standard represents a paradigm shift for textile manufacturers, particularly those producing water-repellent products like umbrellas.

Why This Matters Now: The regulation entered into force on October 10, 2024, with enforcement beginning October 2026 for most textile products. Manufacturers who fail to adapt face market exclusion, product recalls, and significant financial penalties across the entire EU market.

Topumbrella has proactively addressed these challenges, having successfully passed PFAS-free testing using the new EN 17681-1 standard. Our certified compliance ensures that brands and retailers partnering with us can confidently enter the EU market without regulatory risks, demonstrating our commitment to environmental responsibility and regulatory foresight.

For global brands and EU buyers, this compliance advantage translates to reduced supply chain risks, accelerated time-to-market, and enhanced brand reputation. As consumer awareness of PFAS dangers grows, partnering with a verified PFAS-free manufacturer isn't just about compliance—it's about competitive advantage and corporate responsibility.

2. What Are PFAS and Why Do They Matter in Umbrella Manufacturing?

Understanding "Forever Chemicals"

PFAS are synthetic chemicals containing fluorinated carbon chains that create extraordinarily strong carbon-fluorine bonds. This molecular structure makes them virtually indestructible in natural environments, earning them the notorious moniker "forever chemicals." The Organisation for Economic Co-operation and Development (OECD) defines PFAS as any chemical containing at least one fully fluorinated methyl or methylene carbon atom.

Environmental and Health Concerns:

- Bioaccumulation: PFAS accumulate in human blood, liver, and kidneys over time, with half-lives measured in years

- Environmental Persistence: Once released, PFAS contaminate soil, groundwater, and drinking water for generations

- Health Effects: Associated with increased cholesterol, thyroid disorders, immune system suppression, and certain cancers

- Ecosystem Impact: Disrupts aquatic life, wildlife, and enters the food chain through contaminated water and soil

PFAS in Umbrella Manufacturing: Hidden Sources

Umbrellas are particularly susceptible to PFAS contamination due to their functional requirements for weather protection. Common sources include:

- Water-Repellent Coatings (DWR): C6 and C8 fluorinated polymers traditionally used for hydrophobic treatments on canopy fabrics

- Oil-Repellent Finishing: Fluorochemical treatments preventing staining from oils, dirt, and pollutants

- UV-Protective Coatings: Some UV-blocking treatments incorporate PFAS-based additives for enhanced durability

- Fabric Lamination & Treatment: Adhesives and bonding agents in multi-layer fabrics may contain PFAS precursors

- Printing Inks and Dyes: Screen printing processes sometimes use PFAS-containing surfactants and leveling agents

- Adhesives and Tapes: Structural adhesives, seam tapes, and binding materials in umbrella construction

- Trims and Accessories: Zippers, buttons, elastic bands, and decorative elements with protective coatings

The complexity of umbrella supply chains means that even manufacturers using PFAS-free primary materials face contamination risks from upstream suppliers. Raw material traceability and comprehensive testing across all components are essential for genuine PFAS-free compliance.

3. Understanding REACH REGULATION (EU) 2024/2462: Requirements & Enforcement Timeline

What the Regulation Controls

Regulation (EU) 2024/2462 adds Entry 79 to Annex XVII of the REACH Regulation, specifically targeting PFHxA and related substances. This represents a strategic response to industry substitution patterns, as PFHxA had widely replaced the previously banned PFOA (perfluorooctanoic acid).

Regulated Substances:

- Undecafluorohexanoic acid (PFHxA) and its salts

- PFHxA-related substances: Any compound that can degrade or transform into PFHxA based on molecular structure

- Substances with linear or branched perfluoropentyl groups (C5F11-)

- Substances with linear or branched perfluorohexyl groups (C6F13-)

Critical Limit Values

The regulation establishes strict concentration thresholds measured in homogeneous materials:

- PFHxA and its salts: Maximum 25 parts per billion (ppb)

- PFHxA-related substances: Maximum 1,000 ppb total

Enforcement Timeline for Textile Products

October 10, 2024

Regulation Enters into Force – Legal framework established across all EU member states

October 10, 2026

Enforcement Begins for Consumer Textiles – Applies to clothing, footwear, accessories, and related textile products including umbrellas. This is the critical compliance deadline for most manufacturers.

October 10, 2027

Extended to All Other Textiles – Covers carpets, curtains, upholstery, and industrial textiles not used in clothing

October 10, 2029

Final Phase-In Complete – Certain specialized applications reach full compliance

Application to Umbrella Products

Umbrellas fall under the October 2026 enforcement deadline as consumer accessories. This means all umbrella canopy fabrics, coatings, and related components must comply with the PFHxA limits by this date. Manufacturers must ensure:

- All canopy fabrics meet the 25 ppb limit for PFHxA

- Water-repellent treatments contain no PFHxA-related substances above 1,000 ppb

- Complete supply chain documentation proves compliance

- Testing certificates from accredited laboratories using approved methods

Importantly, the regulation contains exemptions for certain personal protective equipment (PPE) in risk category III and medical devices, but standard consumer umbrellas receive no such exemptions. More information on the complete regulation is available on the EUR-Lex official portal.

4. EN 17681-1:2023 / 2025 — The New PFAS Testing Standard

Background and Development

The European Committee for Standardization (CEN) first published EN 17681-1 in 2022, but quickly recognized its limitations in detecting polymeric PFAS compounds. Following extensive research and consultation, CEN released a draft standard prEN 17681-1:2023 in December 2023, which was officially published as EN 17681-1:2025 in April 2025.

This rapid evolution reflects the urgency of closing regulatory loopholes that allowed side-chain fluorinated polymers to evade detection while still contributing to environmental PFAS contamination. The SGS testing laboratory and other leading certification bodies have endorsed this method as the new industry benchmark.

Revolutionary Alkaline Hydrolysis Method

The defining innovation of EN 17681-1:2025 is its use of alkaline hydrolysis during extraction. This process employs a methanol/sodium hydroxide solution that:

- Breaks down polymeric fluorinated structures into detectable monomers

- Releases side-chain fluorinated compounds previously bound to fabric substrates

- Degrades ester-based polymers containing fluorotelomer alcohols (FTOHs)

- Exposes PFOA and C9-C14 PFCA-related substances hidden in polymer matrices

Analytical Technology: Following alkaline hydrolysis extraction, samples undergo analysis using Liquid Chromatography-Tandem Mass Spectrometry (LC-MS/MS), providing precise identification and quantification of specific PFAS compounds.

Expanded Analyte Coverage

EN 17681-1:2025 targets a comprehensive list of PFAS compounds, including:

- Perfluoroalkyl carboxylic acids (PFCAs): C6 through C14 chain lengths

- Perfluoroalkane sulfonic acids (PFSAs): PFOS, PFHxS, and related compounds

- Fluorotelomer alcohols (FTOHs): 4:2, 6:2, 8:2, and 10:2 variants

- Side-chain fluorinated polymers and their degradation products

- Fluoroacrylate polymers that release PFAS during hydrolysis

- Precursor substances that transform into regulated PFAS

Key Differences from Previous Methods

| Aspect |

EN 17681-1:2022 (Old) |

EN 17681-1:2025 (New) |

| Extraction Method |

Methanol only |

Methanol + alkaline hydrolysis |

| Detects Polymeric PFAS |

No |

Yes |

| FTOH Detection Rate |

Low (free FTOHs only) |

Significantly higher |

| Detection Limits |

Higher thresholds |

Lower, more sensitive |

| Regulatory Alignment |

Partial compliance |

Full REACH/POPs compliance |

Critical Impact: Internal studies show that products passing under EN 17681-1:2022 methodology frequently fail when tested using EN 17681-1:2025. The detection rate for certain PFAS analytes, particularly fluorotelomer alcohols, increases dramatically—sometimes by 500% or more. Manufacturers relying on old test results face significant compliance risks.

Implementation Timeline and Industry Adoption

The European Committee for Standardization officially published EN 17681-1:2025 on April 30, 2025, with national standardization bodies required to adopt it by October 2025. However, leading brands and industry groups are already requiring this testing method:

- AFIRM (Apparel & Footwear International RSL Management): Updated their 2025 Restricted Substances List to reference the new method

- Major Retailers: Decathlon, IKEA, and other European retailers have incorporated EN 17681-1:2025 into supplier requirements

- International Brands: Global outdoor and apparel brands are proactively adopting the standard ahead of enforcement

Topumbrella recognized this shift early, completing comprehensive testing using the EN 17681-1:2025 methodology months before its official publication. This forward-thinking approach ensures our products meet not just today's requirements, but tomorrow's standards.

5. Europe's Increasing PFAS Restrictions: Future Plans & Phase-Out Timeline

The Universal PFAS Restriction Proposal

On January 13, 2023, authorities from Denmark, Germany, the Netherlands, Norway, and Sweden jointly submitted an unprecedented Annex XV restriction proposal to the European Chemicals Agency (ECHA), targeting approximately 10,000 PFAS substances. This proposal represents the most ambitious chemical restriction in EU history, aiming to eliminate nearly all PFAS uses where safer alternatives exist.

Following an extensive public consultation that received over 5,600 responses totaling more than 100,000 pages of technical documentation, ECHA updated the proposal in August 2025 to include eight additional sectors and refined regulatory approaches. The proposal is currently under evaluation by ECHA's Risk Assessment Committee (RAC) and Socio-Economic Analysis Committee (SEAC).

Projected Timeline to Near-Total PFAS Phase-Out

2024–2025

PFHxA & C6/C14 Restrictions – Current regulations targeting specific PFAS compounds in effect (EU 2024/2462)

Late 2025/Early 2026

ECHA Committee Opinions Expected – RAC and SEAC to deliver final scientific and socio-economic assessments

2026–2027

European Commission Decision – Draft restriction regulation based on committee opinions; Council and Parliament scrutiny

2027–2028

Potential Adoption of Universal PFAS Ban – Comprehensive restriction could enter into force with transition periods of 5-12 years depending on application

2030+

Broad PFAS Phase-Out Completion – Most consumer products, textiles, and non-essential applications must be PFAS-free

National Initiatives Setting Earlier Deadlines

Several EU member states are implementing stricter regulations ahead of the universal restriction:

France

In February 2025, France passed landmark legislation banning PFAS in:

- January 1, 2026: Cosmetics, ski wax, and waterproofing agents

- January 1, 2030: All textile products (with limited exemptions for essential uses)

- Includes "polluter pays" provision: €100 fine per 100 grams of PFAS released

Denmark

Denmark proposed national legislation targeting PFAS in clothing, shoes, and waterproofing products, potentially effective by 2026, establishing it as one of Europe's strictest regimes.

What Global Brands Are Already Demanding

Leading international brands aren't waiting for final regulations. Major players have established voluntary PFAS elimination timelines:

- Patagonia: Committed to 100% fluorine-free DWR treatments by 2025

- H&M Group: Phasing out all PFAS across product categories

- IKEA: Prohibits PFAS in textile products company-wide

- Decathlon: Implementing comprehensive PFAS testing and elimination programs

- Adidas & Nike: Actively transitioning to fluorine-free water-repellent technologies

Strategic Implication: The regulatory trajectory is unmistakable—PFAS elimination is not a question of "if" but "when." Manufacturers who proactively eliminate PFAS now will avoid costly reformulations, maintain market access, and gain competitive advantages as restrictions tighten. Waiting until enforcement begins risks supply chain disruptions, stranded inventory, and loss of key customers.

The European Commission's 2025 Chemicals Industry Action Plan reinforced the "essential use" principle, stating PFAS should only remain in applications where use is absolutely indispensable for health, safety, or societal functioning with no viable alternatives. Consumer textiles, including umbrellas, definitively do not qualify for essential use exemptions. Learn more about the universal PFAS restriction at the European Chemicals Agency.

6. What This Means for Manufacturers and Importers

Escalating Testing Requirements

The new regulatory landscape dramatically expands testing obligations. Previously, manufacturers might test only primary canopy fabrics. Now, comprehensive PFAS testing must cover:

- All fabric layers and coatings

- Printed areas and dye applications

- Seam tapes and binding materials

- Handle materials and grips

- Storage sleeves and cases

- Zippers, buttons, and fasteners

- Labels, hang tags, and packaging

Each material category requires testing under EN 17681-1:2025, with costs typically ranging from $200-$500 per test depending on the analytical scope and laboratory. For a complete umbrella with multiple material types, total testing costs can easily exceed $2,000-$3,000 per product line.

Severe Consequences of Non-Compliance

The financial and reputational risks of PFAS non-compliance are substantial and multifaceted:

Financial Penalties and Costs:

- Border Rejections: Shipments failing compliance checks are refused entry, with goods destroyed or returned at manufacturer expense

- Product Recalls: Post-market surveillance can trigger mandatory recalls affecting entire product lines, with costs averaging 10-30% of total revenue for affected products

- Regulatory Fines: EU member states impose penalties ranging from €5,000 to €500,000+ per violation, depending on severity and jurisdiction

- Market Surveillance Costs: Testing expenses, legal fees, and administrative overhead for compliance investigations

- Inventory Write-Offs: Non-compliant stock becomes unsaleable in the EU market, potentially representing millions in stranded inventory

Supply Chain Complexity and Traceability Challenges

Achieving genuine PFAS-free status requires unprecedented supply chain transparency. Manufacturers must:

- Chemical Disclosure: Obtain complete Material Safety Data Sheets (MSDS) and technical data sheets from all suppliers, including granular chemical composition details

- Multi-Tier Traceability: Map and monitor suppliers beyond first-tier vendors, extending to raw material producers and chemical formulators

- Continuous Verification: Implement ongoing testing protocols as suppliers may reformulate without notice

- Documentation Systems: Maintain comprehensive records proving PFAS-free status throughout product lifecycle

Many manufacturers discover that their Tier 2 and Tier 3 suppliers lack visibility into their own chemical inputs, creating blind spots that expose the entire supply chain to compliance risks.

Transition to Non-Fluorinated DWR Technologies

The technical challenge of replacing fluorinated water-repellent treatments is significant but surmountable. Non-fluorinated alternatives include:

- Hydrocarbon-Based DWR: Paraffin wax and silicone-based treatments offering good water repellency but requiring more frequent reapplication

- Dendrimer Technology: Advanced hyperbranched polymers creating micro-structured surfaces with enhanced durability

- Biomimetic Coatings: Nature-inspired treatments mimicking lotus leaf structures for water beading

- Nano-Silica Treatments: Creating superhydrophobic surfaces through textured nanoparticle coatings

While these alternatives historically underperformed compared to C6/C8 fluorocarbons, recent innovations have narrowed the performance gap significantly. However, reformulation requires extensive testing to ensure water repellency, durability, fabric compatibility, and aesthetic quality meet customer expectations.

Critical Risks for Unprepared Suppliers

Manufacturers who delay PFAS compliance face cascading business consequences:

- Loss of EU Buyers: Major retailers and brands are actively consolidating supplier bases around certified PFAS-free manufacturers. Once dropped from approved vendor lists, reinstatement is extremely difficult.

- Project Delays: Last-minute material changes and reformulation cycles can delay product launches by 6-12 months, missing critical seasonal windows.

- Escalating Lab Costs: Rush testing to meet compliance deadlines incurs premium fees, sometimes 50-100% above standard rates.

- Brand Damage: Public PFAS violations generate negative media coverage and consumer backlash, with reputational damage extending far beyond the specific product.

- Competitive Disadvantage: While laggards scramble to comply, proactive competitors gain market share and strengthen customer relationships.

Timeline Urgency: With October 2026 enforcement approaching, manufacturers need at least 12-18 months for complete PFAS elimination programs including: material sourcing, formulation optimization, comprehensive testing, supply chain certification, and customer validation. Companies starting in late 2025 face severe time constraints.

The strategic imperative is clear: Companies must test early, transition to verified PFAS-free materials, and establish robust compliance systems before EU deadlines. Reactive approaches virtually guarantee business disruption, while proactive strategies create lasting competitive advantages in an increasingly regulated global marketplace.

7. Topumbrella's Advantage: Early Testing, Verified PFAS-Free, and Future-Ready Materials

Proactive Regulatory Tracking Since 2023

While many manufacturers waited for final regulations, Topumbrella began monitoring EU PFAS developments in early 2023, immediately recognizing the strategic importance of early compliance. Our regulatory affairs team tracked:

- ECHA's Annex XV universal PFAS restriction proposal and public consultations

- Development of EN 17681-1 testing methodology revisions

- National initiatives in France, Denmark, and other leading EU states

- Brand requirements from major international retailers

- Chemical industry innovations in fluorine-free technologies

This intelligence gathering enabled us to anticipate regulatory trends and invest in compliance infrastructure before enforcement deadlines created market pressures.

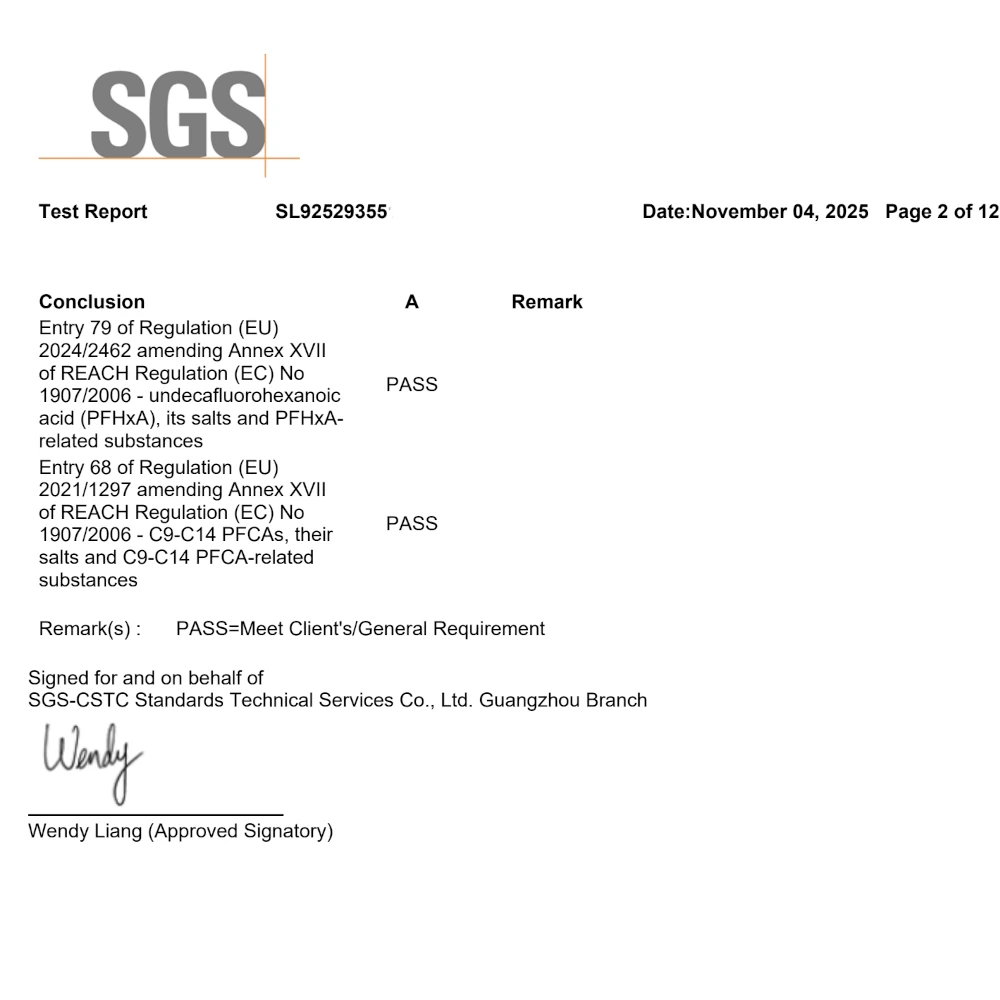

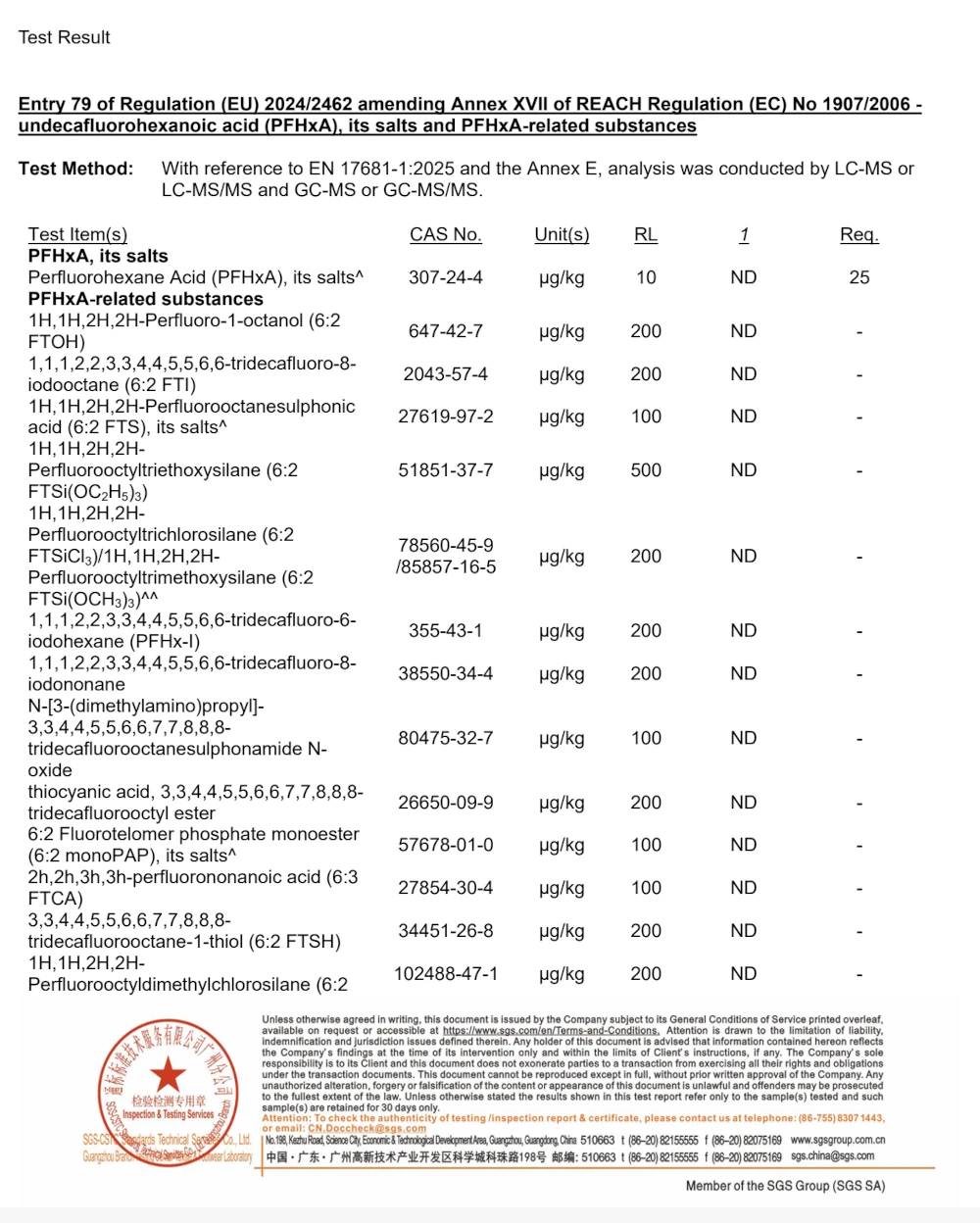

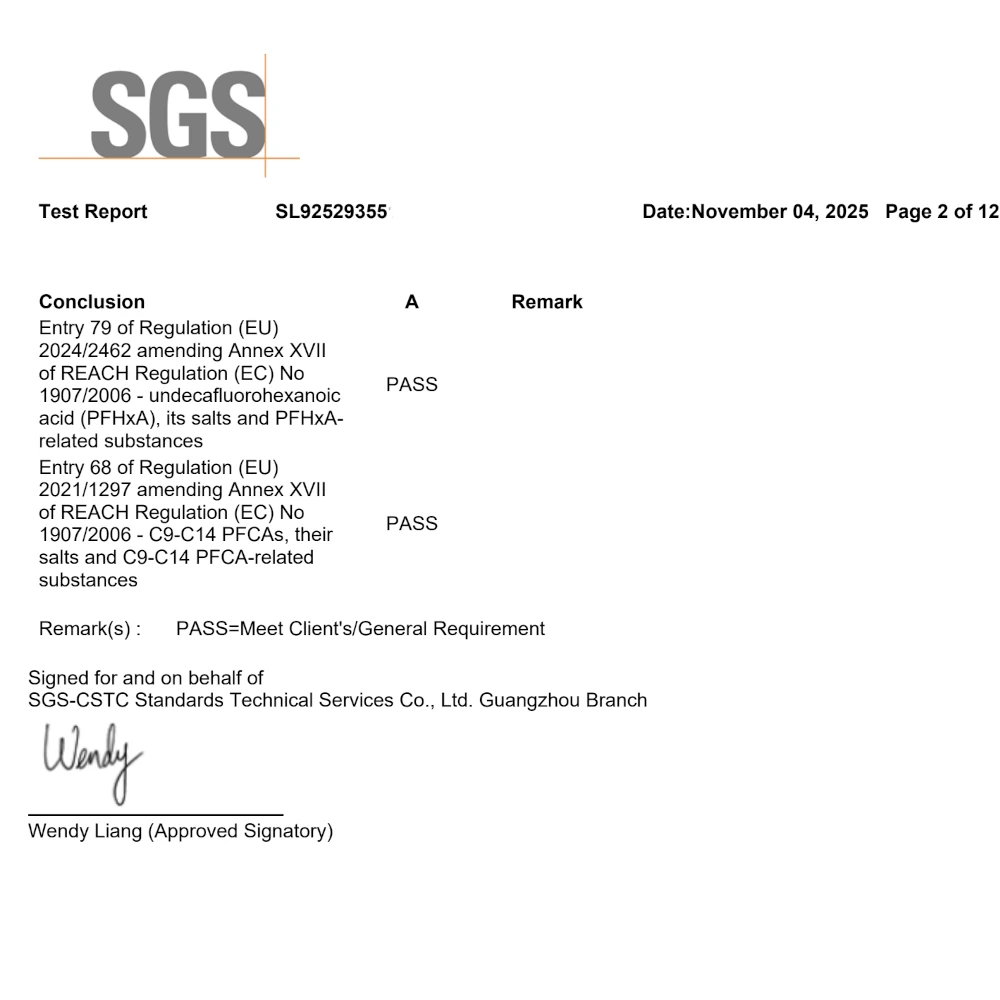

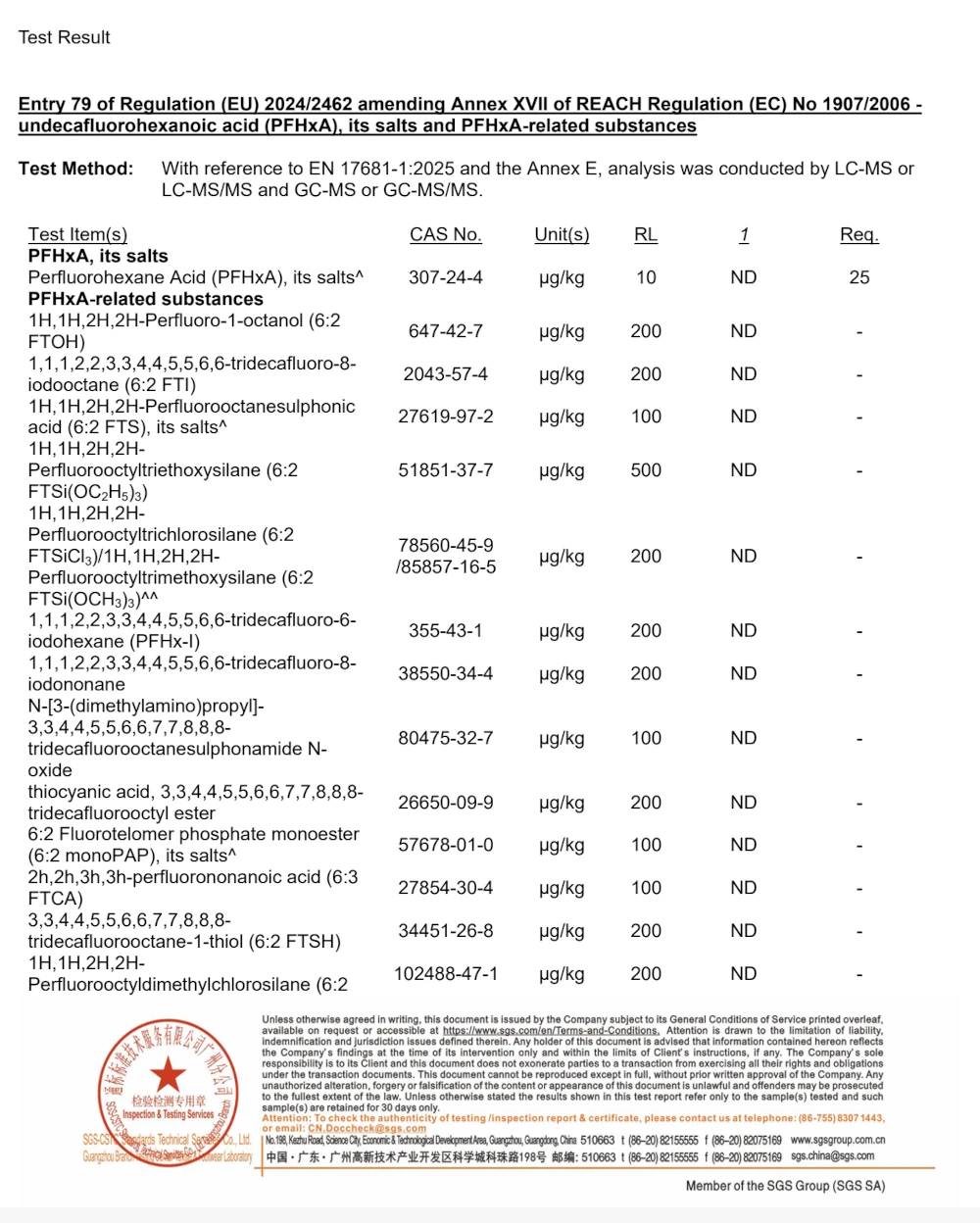

Verified PFAS-Free Certification Using EN 17681-1:2025

In 2025, Topumbrella partnered with SGS, the world's leading testing and certification organization, to conduct comprehensive PFAS analysis using the cutting-edge EN 17681-1:2025 methodology. Our testing program included:

- Complete Material Coverage: All canopy fabrics, coatings, printing inks, seam tapes, and structural components

- Multiple Product Lines: Standard umbrellas, compact umbrellas, golf umbrellas, and specialty designs

- Stringent Detection Limits: Analysis detecting PFAS compounds down to parts-per-billion (ppb) levels

- Full Analyte Panel: Testing for all regulated PFAS including PFHxA, PFOA, PFOS, FTOHs, and side-chain fluorinated polymers

Test Results: Topumbrella's materials successfully passed PFAS-free certification, with non-detectable levels across all tested analytes. This certification validates our material selection strategy and provides customers with legally defensible proof of compliance.

Our PFAS-Free Material Strategy

Achieving genuine PFAS-free status required comprehensive reformulation across our entire product portfolio:

Advanced Water-Repellent Technologies

- Fluorine-Free DWR Coatings: Proprietary hydrocarbon-based treatments delivering excellent water beading and repellency comparable to traditional C6 chemistries

- Durable Performance: Our non-fluorinated treatments maintain water repellency through multiple wet-dry cycles, addressing the primary historical limitation of PFAS alternatives

- Breathability Optimization: Coatings engineered to preserve fabric breathability while blocking water penetration

Sustainable Fabric Innovation

- Recycled PET (RPET) Materials: Canopy fabrics manufactured from post-consumer recycled polyester, reducing environmental impact while maintaining performance

- Biodegradable Options: Developing next-generation materials with end-of-life biodegradability for environmentally conscious brands

- Natural Fiber Blends: Combining synthetic performance with natural fiber aesthetics for premium product lines

Clean Chemistry Throughout Production

- PFAS-Free Printing Systems: Water-based and solvent-based inks formulated without fluorinated surfactants or additives

- Adhesive Selection: Bonding agents and structural adhesives verified free from PFAS precursors and side-chain fluoropolymers

- Component Screening: Rigorous supplier qualification ensuring all trims, zippers, and accessories meet PFAS-free standards

Rigorous Supplier Control and In-House Testing

Supply chain integrity is the foundation of our PFAS-free guarantee. Topumbrella implements:

- Supplier Certification Program: All material suppliers must provide third-party PFAS-free test reports and chemical disclosure documentation

- Incoming Material Inspection: Random batch testing of received materials to verify supplier claims and detect any formulation changes

- In-House Laboratory: On-site testing capabilities for preliminary screening, enabling rapid quality control before external certification

- Traceability Systems: Digital material tracking from raw chemical suppliers through finished goods, creating complete audit trails

- Continuous Monitoring: Periodic re-testing of established materials to detect any supply chain variations

Customer Assurance and Market Advantages

Partnering with Topumbrella delivers tangible benefits for brands and retailers:

Risk-Free EU Market Access:

- ✓ Products certified compliant with current and anticipated PFAS regulations

- ✓ No risk of border rejections or post-market recalls

- ✓ Comprehensive documentation supporting customs clearance and market surveillance inquiries

- ✓ Immediate market readiness—no reformulation delays

Enhanced Brand Reputation:

- ✓ Demonstrate environmental leadership through third-party verified PFAS-free products

- ✓ Align with consumer demand for sustainable, chemical-free products

- ✓ Meet corporate sustainability commitments and ESG reporting requirements

- ✓ Differentiate from competitors still using legacy fluorochemical treatments

Future-Proof Supply Chain:

- ✓ Compliance strategy aligned with EU's long-term universal PFAS restriction plans

- ✓ No need for costly reformulation as regulations tighten

- ✓ Stable supply relationship insulated from regulatory disruptions

- ✓ Early mover advantage in transitioning to post-PFAS textile technologies

Leading PFAS-Free Umbrella Manufacturing for Global Markets

Topumbrella positions itself as more than a manufacturer—we are a strategic compliance partner for brands navigating the complex transition to PFAS-free products. Our investments in testing, material innovation, and supply chain transparency represent a fundamental commitment to environmental responsibility and regulatory excellence.

As PFAS restrictions expand globally beyond the EU to markets including Canada, several U.S. states, and Asia-Pacific regions, our compliance infrastructure creates scalable advantages across multiple jurisdictions. Customers benefit from working with a manufacturer that doesn't just meet today's requirements but actively shapes tomorrow's sustainable manufacturing standards.

Get Your PFAS-Compliant Umbrella Solutions Today

Don't wait until EU enforcement begins. Partner with Topumbrella for certified PFAS-free umbrellas that protect your brand, satisfy regulators, and meet consumer demand for sustainable products.

Request PFAS-Free Test Report Start Your Compliant Project Get PFAS-Free Quote

Contact our regulatory compliance team to discuss your specific requirements and learn how Topumbrella's PFAS-free solutions can secure your EU market access.